Roland DWX-53DC Dry Dental Milling Machine with Automatic Disc Changer

NEW DWX-53DC Dry Dental Milling Machine with Automatic Disc Changer

DGSHAPE takes a purpose-driven approach to the process of innovation. It’s a combination of product and opportunity that enables us to consistently deliver quality and value to the dental lab community. This well-structured solution is in a class of its own, the NEXT GENERATION of DWX…the new DWX-53DC.

- Redesigned spindle for 3x gripping power

- 4mm tool for faster roughing of PMMA, exclusive to DWX-53DC

- Includes dedicated extraction unit and connection cable

- Built-in fully integrated webcam allows for real-time monitoring either on-site or remotely

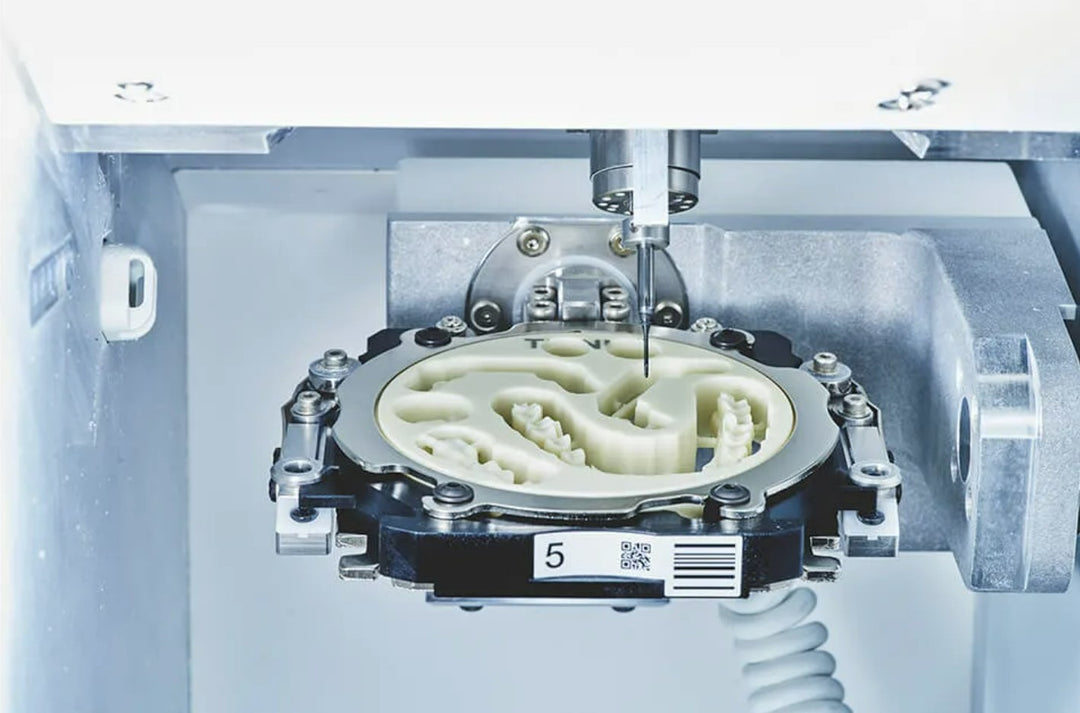

All-New Redesigned, More Robust User-Replaceable Spindle

The DWX-53DC features an all-new redesigned, more robust, user-replaceable spindle for 3x tool gripping power for more efficient, predictable milling of PMMA applications. The user-replaceable spindle can be replaced effortlessly in a matter of minutes, without the need to call or schedule a service technician. No special tools, testing, or training are required.

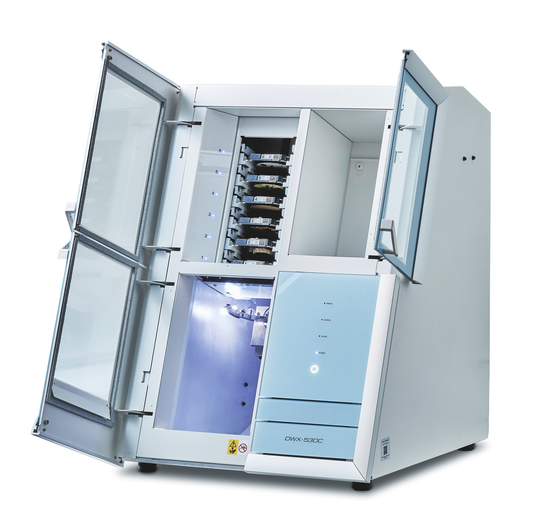

Unattended, Intelligent, 24-Hour Productivity

The All-New DWX-53DC dental milling machine is equipped with a fully integrated webcam for 24-hour remote monitoring and milling capabilities. It's as simple as 1,2,3... Power it on, let it go, and automatically mill a full-range of quality restorations with complete unattended confidence.

Automatic-Disc Changer (ADC)

The DWX-53DC's new enhanced disc changer has a 50% faster disc exchange for increased production with 24-hour milling capacity and capabilities. Load up to six material disc adapters to include a combination of materials to suit the needs of your business and let the DWX-53DC go to work.

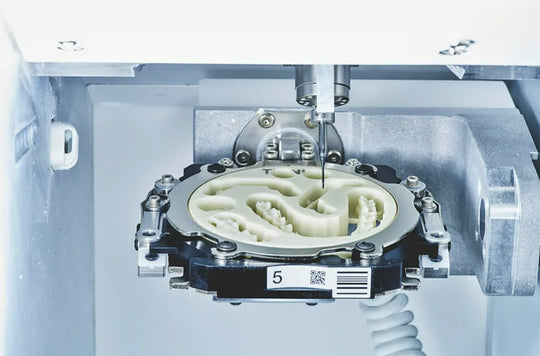

5-Axis Milling

A smooth and steady ball screw-driven system provides superior milling results — simultaneously rotating and tilting discs for deep undercuts and also milling large arch restorations and other full-mouth prosthetics.

Intelligent Tool Control (ITC)

DGSHAPE's proprietary VPanel software simplifies operation. The ITC function automatically swaps out tools that have reached their designated lifespan eliminating time-consuming production errors and interruptions.

Automatic Pressure Control

DGSHAPE's automated regulator eliminates the need for manual air control adjustments by changing air volume based on material data via the CAM software.

![]()

New Automated Eco-System

A cleaner workspace makes for a more productive workspace. The DWX-53DC's new automated eco-system promotes cleaner milling and less machine maintenance with included dedicated extraction unit and connection cable.

![]()

New Fully-Integrated Webcam

Seeing is Believing. The NEW integrated Webcam allows for monitoring from anywhere, anytime on any device.

Highest Clinical Standards

The DWX-53DC is as a Class I medical device with the art of craftsmanship and unsurpassed quality. With its build quality and in accordance with the highest Japanese industrial standards, it gives users added assurance should any compliance laws change.

Specifications

| DWX-53DC | ||

| Compatible Materials | PMMA, Zirconia, Wax, Composite Resin, PEEK, Gypsum, Glass-Fiber-Reinforced Resin, Pre-Sintered Chromium Cobalt | |

|---|---|---|

| Spindle Speed | 30,000 RPM | |

| Rotary Axis | A | ± 360° |

| B | ± 35° | |

| Air Pressure Requirements | 0.4 Mpa | |

| External Dimensions | Width, Depth, Height | 23.62 in. x 29.25 in. x 32.75 in. |

| Weight | 264.55 lbs. (120 kg) | |

| Disc Changing Time | 1 minute, 7 seconds | |

| Material Adapter Compatibility | Standard Adapter: ZMA-53DC | Open-Edge Adapter: ZMA2-53DC |

| # of Material Adapter Patterns | 100 | |

| Additional Features | Redesigned, more robust spindle for 3x the gripping power with PMMA applications. Built-In Integrated Webcam, Automatic Extractor Filter Cleaning, Thermohydrometer Accelerometer Sensors | |

| Accessories Included | Dedicated Extraction Unit and Connection Cable, Built-In Integrated Webcam, Material Adapter Disc Rack (ZR-53DC), Standard Material Adapters (6-Pack, ZMA-53DC), Open-Edge Material Adapter (ZMA-53DC), 4.0 mm Roughing Tool (ZRB-200D), Diamond-Like Coated (DLC) Milling Tool Set (ZPB-100D, ZPD-50D, & ZPB-30D) | |

| Attachable Bur | Shank 4 mm (Diameter), 40-55 mm (Length) | |

| Loadable Workpiece | Step Section: 98.5 mm Diameter, 10 mm Height; Body Section: Max Height 60 mm | |

| Power requirements | AC 100 V to 240 V ±10%, 50/60 Hz, 2.8 A (overvoltage category II, IEC 60664-1) | |

| Power consumption | Approx. 250 W | |